As for the quality of steel, the usual production range provides:

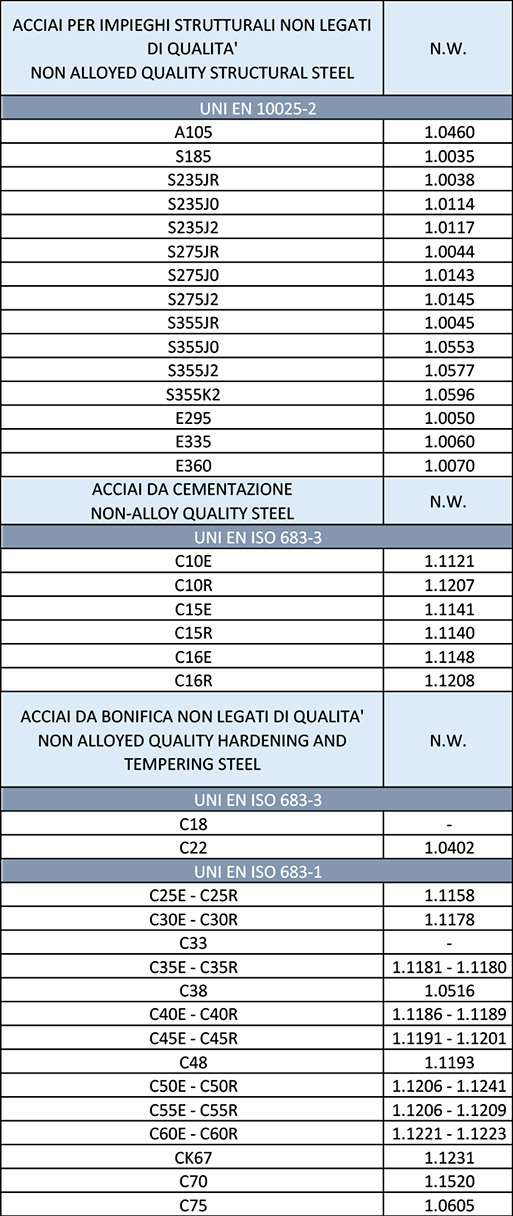

STRUCTURAL STEELS

Structural steels are designed for use in construction and infrastructure, such as buildings, bridges and other load-bearing structures. These steels have high mechanical strength and durability, as well as good weldability and machinability properties, making them ideal for supporting heavy loads and withstanding harsh environmental conditions.

CASE-HARDENING STEELS

Case-hardening steels, characterized by a low carbon content, are intended to undergo a thermochemical treatment called carburizing, which increases surface hardness while maintaining a tough and ductile core. Because of these characteristics, the most common use of these steels is to make mechanical parts stressed by torsional forces at the core and wear at the edges of parts, such as gears, shafts, bushings, and pins.

HARDENED AND TEMPERED STEELS

Hardened and tempered steels have a chemical composition designed to ensure the highest performance following hardening and tempering to improve both mechanical strength and toughness. This process makes them particularly suitable for applications requiring high hardness and resistance to very significant mechanical stresses, such as shafts, connecting rods and machine parts.

FREE CUTTING STEELS

Free cutting steels have a high percentage of sulfur, which improves machinability during automatic cutting and turning operations. Sulfur forms manganese sulfide inclusions that facilitate chip breaking, reducing tool wear and increasing machining speed, making them ideal for mass production of precision mechanical parts.

SPRING STEELS

Spring steels are specially designed for spring manufacturing. Silicon increases the elasticity and fatigue strength of these steels, allowing springs to maintain their shape and performance even under high cyclical loads. These steels are used in a variety of applications, including vehicles and industrial machinery.

MICRO-ALLOYED STEELS

Micro-alloyed steels are enriched with small amounts of elements such as niobium, vanadium, and titanium. These elements improve the mechanical properties of the material, such as strength and toughness, without compromising machinability. Micro-alloyed steels are often used in structural and engineering applications where high performance is required.

MEDIUM-ALLOYED STEELS

Medium-alloyed steels contain alloying elements: Nickel for resilience and fatigue resistance, Chromium for hardness and toughness, Molybdenum to reduce brittleness upon tempering, and Manganese. These elements, in variable contents, improve the mechanical properties and corrosion resistance of the material, making them suitable for applications requiring a combination of strength, hardness, and toughness, such as machinery components and industrial equipment.

TOOL STEELS

Tool steels are formulated for the manufacture of cutting tools, dies and mechanical machining equipment. These steels are characterized by high hardness, wear resistance and sharp edge retention, even at high temperatures, making them ideal for applications requiring precision and durability.

BEARING STEELS

Bearing steels have a high chromium content, designed to fabricate ball and roller bearings. These steels are characterized by high hardness, wear and fatigue resistance, and dimensional stability, ensuring reliable performance and long life under load and cyclical motion.

BORON STEELS

Boron-alloyed special steels are enriched with moderate amounts of alloying elements such as chromium, nickel and boron. The addition of boron improves the hardenability of the steel. These steels are used for bolting and in the tractor industry for parts subject to wear such as tracks, hoes and excavator teeth.

On request, can also be guaranteed the size of austenite grain (ASTM scale), steel purity and control of the micro-inclusions.

Due to the laboratory equipment, including machines for non-destructive (Magnaflux) and mechanical tests, in combination with an optical spectrometer, Metallurgica Marcora is able to supply any kind of product certification such as: cast analysis, tensile strength and hardness.